Europe must take decisive steps to simplify and modernise its rail systems to strengthen competitiveness,...

Smart maintenance concept for maximising efficiency

As a result of the work coming from several different projects funded by Shift2Rail on smart maintenance, a holistic approach for maintenance in the whole railway system using the opportunities afforded by interaction as well as mutual monitoring, has been conceived.

Smart Maintenance (SM) relays on the ‘Internet of Things’ and ‘Computerized Analysis Technologies’ to optimise the maintenance of systems and thus improve safety, reliability, availability and reduce the overall cost of the railway system. This concept goes further than just condition based maintenance, as it integrates a system of system approach, following the evolution of the railway system and its stakeholders to achieve the benefits mentioned above.

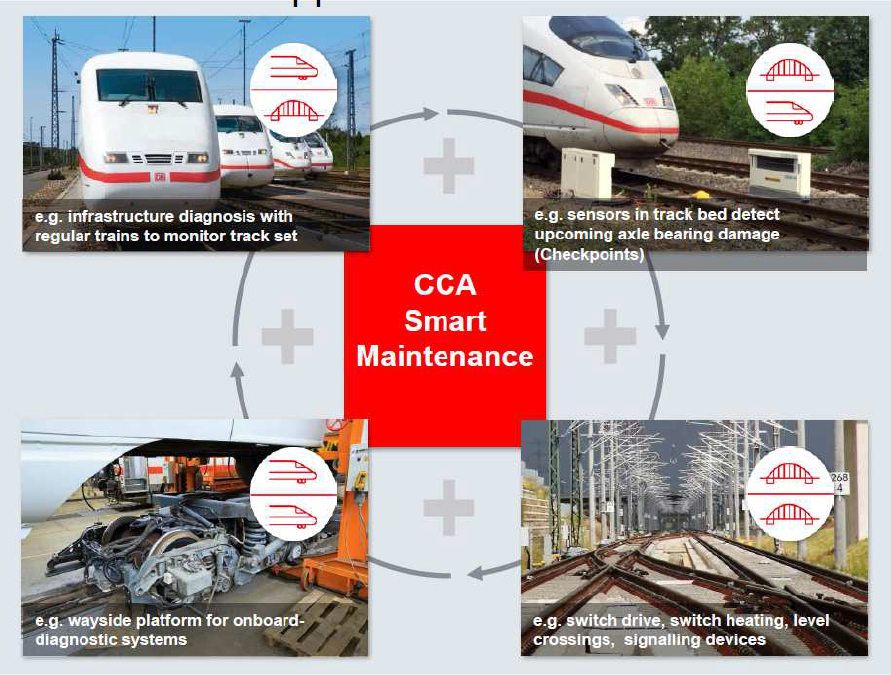

Optimisation realised by the SM system considers the possibilities and advantages from monitoring each of the four stages described in the quadrants below (Image 1). The continuous improvement of safety, reliability and availability and the reduction of the overall cost of the system can only be achieved by a SM that keeps up with the evolution.

Image 1: The four quadrants of smart maintenance

The SM concept proposed in the CCA Work Area provides the possibilities to evolve in an agile manner, so that it would be able to work as a lighthouse and a drive the continuous development of the railway system. Nonetheless, while continuously evolving, the highest degree of the compatibility with the previous versions is needed due to the critical nature of safety in the overall system approach.

The SM concept is based on the following key pillars, which make use of different technological solutions, locations and degrees of integration:

-

-

- Data acquisition based on reliable sensors that may have processing power and embedded intelligence;

- Fast and secure data transmission;

- Data post processing to identify deviations and trends;

- Crossing with maintenance plan, operational and management information or other, for maintenance decision.

-

These pillars form a system that captures raw data, related to the condition of the monitored items, transmits and processes this data to obtain information about the condition of the monitored items and finally relates to other information to suggest decisions for the maintenance, constituting the value chain of smart maintenance.

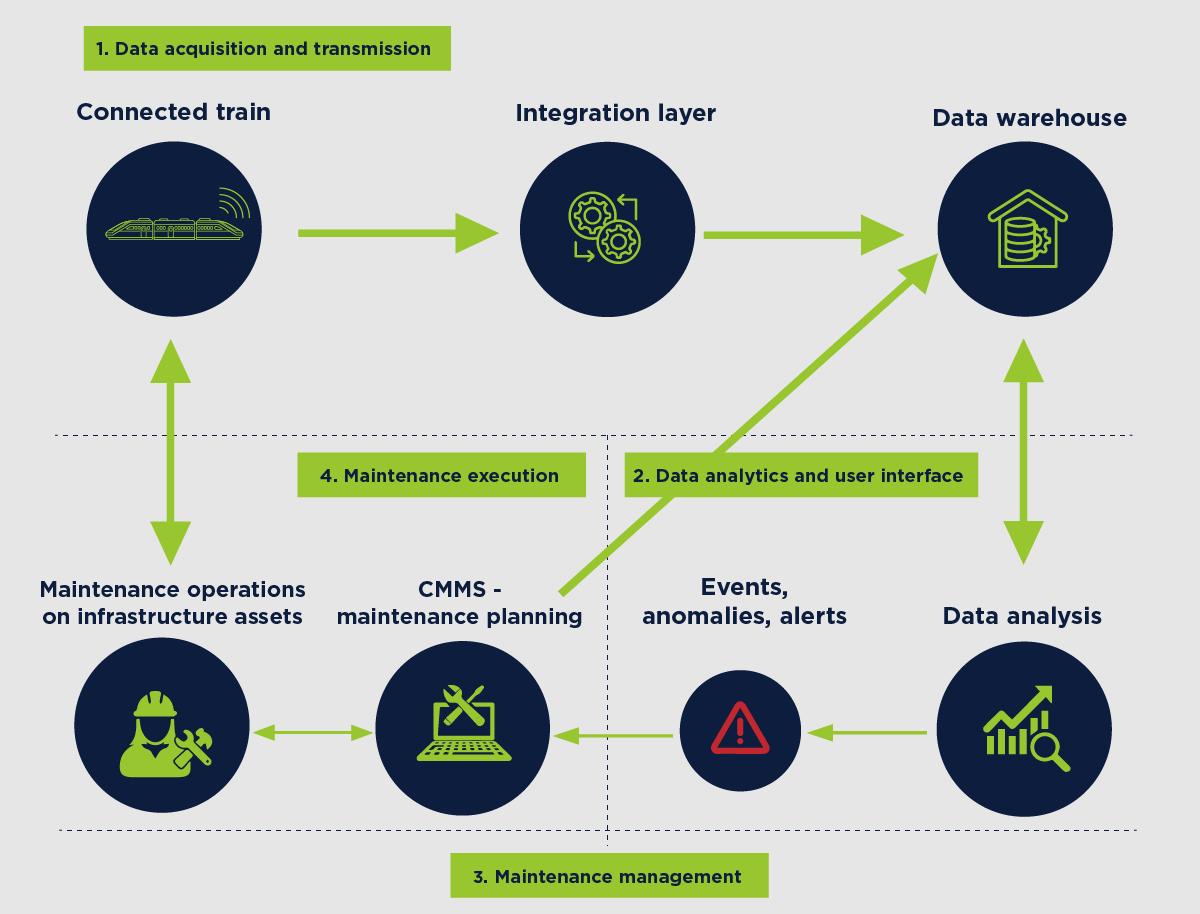

The definition of the value chain of smart maintenance, from data acquisition to maintenance decision support, was key to develop common requirements and guidelines. This data value chain is presented in the following figure.

Image 2: SM data value chain

Value for the railway system.

Current rolling stocks and infrastructure assets in general have limited remote monitoring devices, integrated by design. As a consequence, current maintenance policies integrate human inspections, required for observing and measuring certain variables and detecting possible anomalies. The more rolling stocks and infrastructure assets integrate by design remote monitoring solutions, the more effective the SM solution will be. This will have a significant positive impact on the working conditions of the maintenance staff because there will be less need to carry out on-site work and, in addition, the staff will require new skills such as IT knowledge in order to draw appropriate conclusions with respect to maintenance requirements and efficient operations in the system.

Overall, in order to achieve maximum efficiency, SM approaches and concepts need to be harmonised at the overall railway system level.

New global safety framework

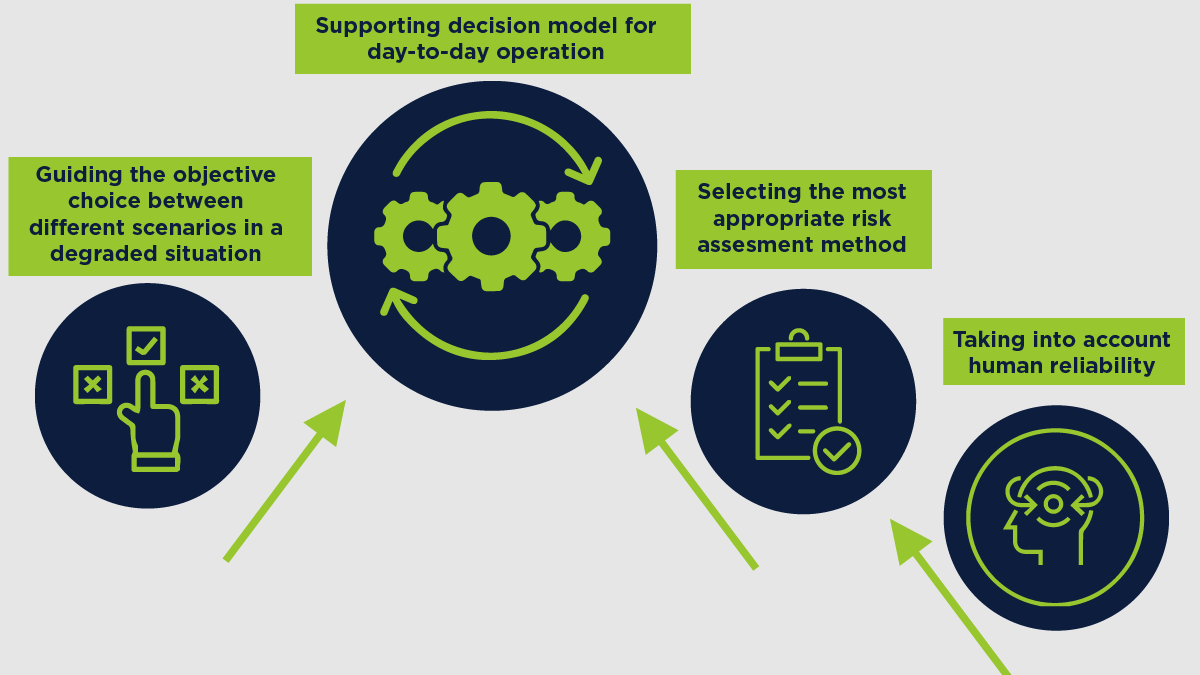

This infographic defines a safety management process of the railway system based on risk assessment, the aim being to support managers in taking safety critical decisions in day-to-day operation.

The decision model developed is based on a global description of the degraded situation to be addressed by both the physical description of the assets and by the identification, analysis and assessment of the risks. At the same time it compares the different scenarios of mitigation of the degraded situation based on a series of safety-related indicators. The model showcases the decision taken by the person in charge, by displaying all this information in a compact and interpretable way.

It also allows to anticipate the impact of new conditions such as change in weather conditions, operational constraints, delays to mitigate the issue, etc. , by simulating their effects based on the chosen indicators. A crucial part of this process is the accurate assessment of the risks associated to the different scenarios, especially the part related to the human factors, which are at the core of many railway operation processes. During the project different methods to quantify the human reliability have been screened and the one specific method proposed by the Rail Safety and Standards Board was tested and implemented.

Image 1: Safety management process