FP2-R2DATO D7.3: Perform simulation with initial implementation of the Data Factory The FP2 R2DATO project advances...

On 21 June 2024, the Governing Board of Europe’s Rail Joint Undertaking (EU-Rail) adopted a Call for Expression of Interest (CEI) with a view to selecting associated members with the potential to contribute to the achievement of its objectives. The Governing Board decision can be accessed here.

Discover detailed information about procurment rules and information.

Access detailed information about past tenders.

Europe's Rail regularly published Calls for Tenders. To find out about open Calls, follow link below.

Article 15 (Principle of transparency) of the EU-Rail financial rules states that the JU shall make available on its internet site no later than 30 June of the following financial year information on the recipients of funds deriving from its budget.

EU-Rail’s Innovation Pillar (IP) is tasked to deliver operational and technological solutions that contribute to a more efficient, flexible, and demand-led, yet safe and environmentally sustainable European railway system.

The System Pillar provides governance, resource, and outputs to support a coherent and coordinated approach to the evolution of the rail system and the development of the system view.

The Deployment Group advises the EU-Rail Governing Board on the market uptake of rail innovation developments and support their deployment.

For a successful and effective implementation of the Digital Automatic Coupler for European rail freight (DAC), it is of crucial importance to have open, close and efficient cooperation between rail stakeholders. The European DAC Delivery Programme enabled by Europe’s Rail, offers a unique European platform for such cooperation and collaboration.

Discover how Europe’s Rail Joint Undertaking is calling for a bold, coordinated investment strategy to simplify and modernise rail systems across the EU. This public-private partnership model – outlined in our High-Level Paper – proposes an €18 billion investment from 2028 to 2034 to strengthen European competitiveness, deliver greener transport, and drive technological sovereignty.

Discover detailed information on Europe's rail innovation initiatives, showcasing flagship and other projects aimed at enhancing rail systems across Europe. It highlights collaborative efforts funded by the European Union to develop sustainable, efficient, and competitive rail transport solutions.

Europe’s Rail Catalogue of Solutions illustrates successful R&I results in the form of possible products and solutions, while highlighting the benefits for final users, operators, infrastructure managers and/or suppliers. This publication also outlines the advantages of integrating demonstrators into market solutions so that they can deliver the rail innovation Capabilities of the future.

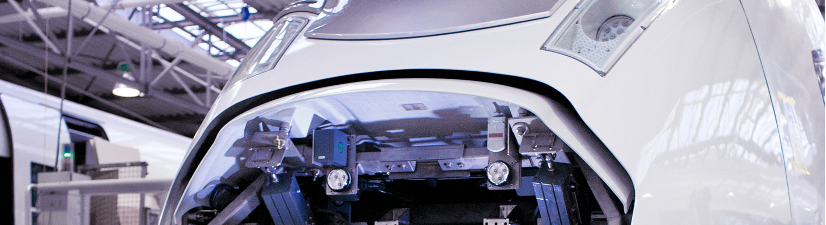

The design of rolling stock plays a key role for the attractiveness of rail transport. Passengers will only prefer to use rail transport over other modes if trains are comfortable, reliable, affordable and accessible. At the same time, the train design must meet the requirements of the railway undertakings and the urban operators (who are the main customers of the rail supply industry), in order to deliver high-quality and cost-efficient services to their customers.

A combination of rail customers’ ever-evolving requirements for rail passenger vehicles is generating a new wave of challenges to rail vehicle development: quality of service, time constraints, mounting energy costs, more stringent emission standards, and increasing stress on the economics of rail operation.

If rail is to compete more effectively with other modes and attract more passengers in the future, it needs a future generation of passenger trains that will be lighter and more energy- and cost-efficient, while at the same time providing a comfortable, safe and affordable travel experience for all passengers.

These innovations should therefore not be limited to the traditional, incremental approach to vehicle development, but should also derive from an entirely new way of thinking on product development.

In order to introduce the future generation of passenger trains, an innovative system approach is needed which includes the development of innovative and modular solutions for comfortable and attractive trains. Other important parts of the holistic passenger train concept are the development and integration of higher-performance technologies for traction and critical structural components, command-control and cabin environment applications, and flexible, reliable and safe design and production solutions. At the same time, innovative solutions need to be developed to extend vehicle lifetime, simplify retrofitting and ensure that networks can support the operation of these vehicles.

Work will be organised around the following Technical Demonstrators (TDs), covering all the R&I areas indicated in the Shift2Rail Master Plan: Traction, Train Control and Monitoring System, Car body shell, Running Gear, Brakes, Doors and intelligent access systems and Train interiors.

A more global view on functional interactions existing between TDs is shown in the figure below, which highlights not only the technological but also the functional interdependencies between TDs, IPs and cross-cutting activities.

The ‘Indicative list of priority research and innovation activities’ in the draft Shift2Rail strategic Multi-Annual Action Plan is available in the Reference Documents > Shift2Rail JU Documents section.