Europe must take decisive steps to simplify and modernise its rail systems to strengthen competitiveness,...

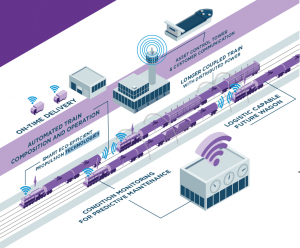

How can we increase the capacity of freight trains while at the same time improving their performance? The Shift2Rail IP5 project Dynafreight presented its results on 27 June in Brussels.

The project paved the way for the regular operation of long trains and the creation of the next generation of bogies of freight locomotives. A bogie, a metal frame to which the axles and wheels is attached, is an essential part of a train as it enables driving through even the sharpest bend as well as it attenuates the impact of track irregularities on the vehicle. Computer-based analysis in different areas has shown the potential of new freight locomotive bogies in comparison to current bogie designs:

- An assessment of light materials has demonstrated that the weight of the bogie frame can be reduced up to 37%.

- Novel steering systems improve curving behaviour with regard to the wheel-rail forces, reducing wheel wear and wheel-track damage resulting in an increase of wheel life by 40%.

- Monitoring solutions can reduce the life cycle cost of bogies by 7%.

- New solutions were tested to reduce rolling noise levels, achieving a reduction of more than 4 dB.

In parallel, the project team has been preparing the ground for regular operations of long freight trains up to 1,500 meters. Currently, freight trains in Europe can be up to 750 meters long. Trains exceeding this standard pose a number of challenges; they are, for instance, less reactive, which raises serious safety concerns. To solve this issue, a second locomotive could be placed in the middle of two linked trains. Connected via a remote control system, both trains can act as one.

In this context, researchers examined Spanish freight train lines to assess the safety issues at stake, the barriers still hindering the operation of long trains as well as the functional requirements of radio-controlled traction and braking. The results will fuel future Shift2Rail projects on freight transportation within the framework of the Innovation Programme 5: Technologies for Sustainable & Attractive European Rail Freight.

Visualisation of Shift2Rail Innovation Programme for Freight (IP5)